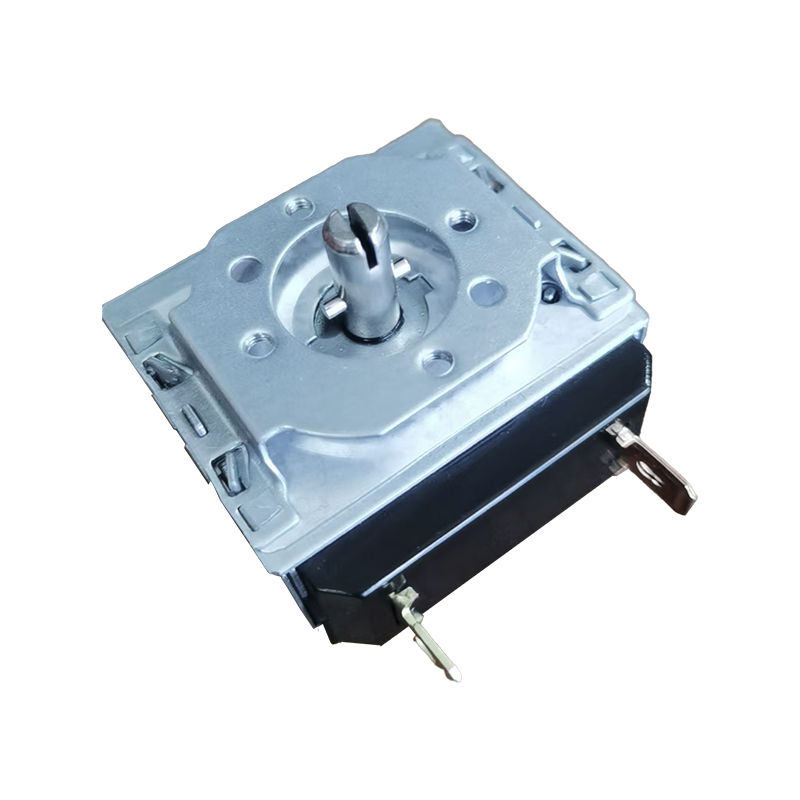

In the field of small appliance manufacturing and repair, mechanical timers have always held a core position due to their simple structure, durability, and strong anti-interference capabilities.

While the principles appear similar on the surface, the core technical parameters must be precisely matched. Although these appliances all rely on mechanical timer switches to control operating time, significant differences exist in practical applications due to variations in electrical loads, ambient temperatures, and vibration frequencies across different application scenarios.

1. Differences in Electrical Load and Contact Capacity

The core function of a mechanical timer is to control current through the opening and closing of internal contacts.

Electric Ovens: Typically have high power (1500W-2000W+), requiring the timer's contact capacity (e.g., 16A/250V) to be sufficient to prevent arcing caused by high current from causing contact sticking.

Air Fryers: Although their power is slightly lower than ovens, due to their compact size, the instantaneous starting current's impact on the timer switch's load cannot be ignored.

Clothes dryers: These involve more inductive loads (motor-driven), which places special demands on the arc erosion resistance of the mechanical timers contacts.

2. Environmental Temperature Rating (T-rated value)

This is a key selling point determining the versatility of a mechanical timer.

Electric ovens have extremely high internal heat radiation, requiring timers to typically achieve a T125 or even higher temperature rating.

Air fryers, while having high-speed fans for cooling, have relatively controllable internal temperatures, but these are still higher than those of ordinary household appliances.

Clothes dryers have a relatively mild environment, but higher humidity. If a low-temperature-resistant timer specifically designed for dryers is incorrectly installed in an oven, the internal lubricant will quickly dry out, and the plastic gears may even deform due to heat, leading to timer failure or a fire hazard.

3. Structural Design and Installation Compatibility

As a professional mechanical timer manufacturer, we design different shafts and mounting plates for different models.

Electric ovens typically require longer shafts to penetrate thick insulation panels.

Air fryers, in pursuit of a stylish appearance, often employ customized "flower shafts" or "D-shaped shafts" to accommodate specific knobs.

The loudness of the bell is also a differentiating factor. Ovens typically require a crisp, single bell, while some dryers may need a more sustained vibration.

4. Timing Accuracy and Logic Function

Although all are called mechanical timers, their timing logic may differ.

Some air fryers require precise 0-30 minute short timers, with a more refined gear ratio design.

Some ovens or dryers require a "Stay On" function, allowing users to operate the appliance for extended periods without timer control.

How to Choose the Right Mechanical Timer?

While mechanical timers are generally universal in their basic mechanical structure, in actual production, precise selection must be made based on the product's power load, temperature limits, installation structure, and certification requirements (such as UL, VDE, CQC, etc.).

As a leading supplier of mechanical timers, we recommend that customers provide the original technical drawings or detailed electrical specifications when replacing or purchasing timers. Blindly mixing and matching appliances can not only shorten their lifespan but also potentially cause serious safety accidents.

If you are looking for high-performance timers for electric ovens, air fryers, or dryers, look for high-quality mechanical timers with high temperature resistance certifications and long cycle life tests.

English

English 中文简体

中文简体