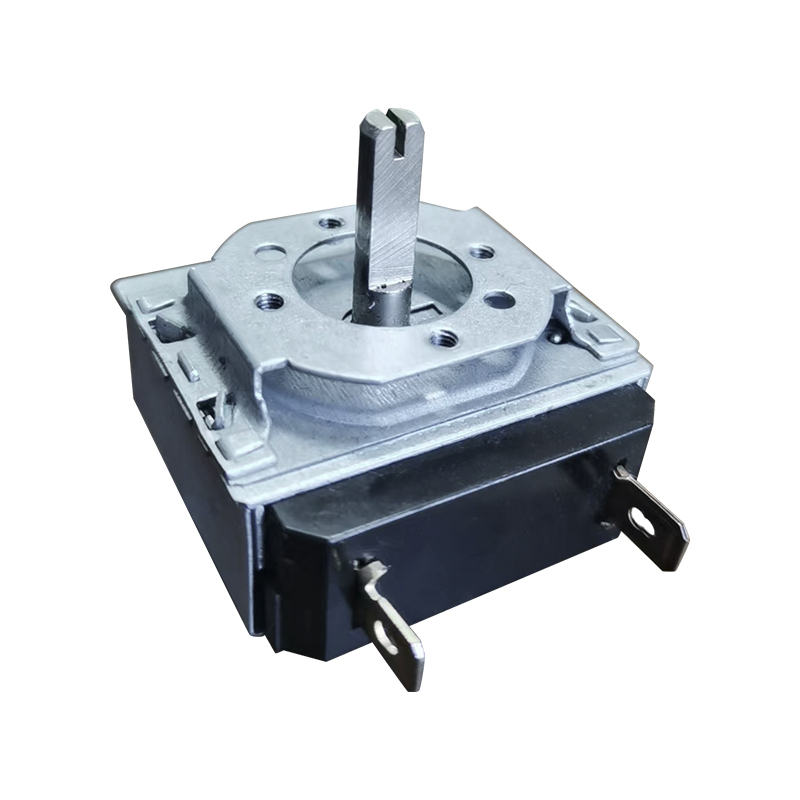

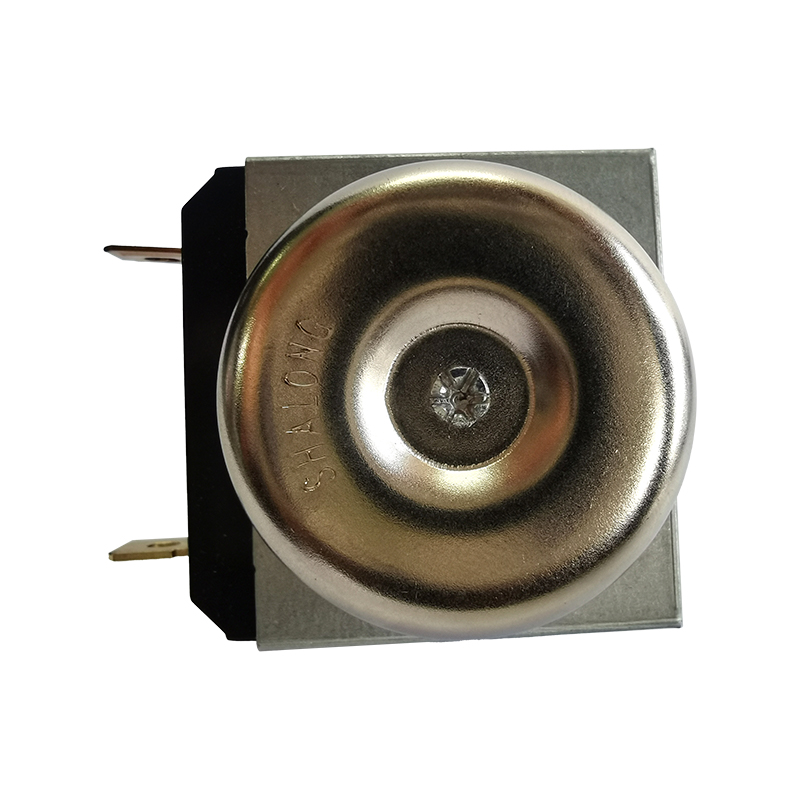

The operating temperature range of the Egg Steamer SL 15-minute Metal Mechanical Timer is -10°C to +125°C, and it can operate normally below 125°C. However, if it is used continuously in a high temperature environment for a long time, especially when it approaches or reaches 125°C, it may have a significant impact on the life and performance of the timer. The following are specific effects of high temperature environments on the components of the timer and suggestions for coping.

The internal structure of the mechanical timer is composed of metal parts such as gears, springs and contacts, which are easily affected by thermal expansion and contraction in a high temperature environment. Long-term high temperatures may cause the metal to expand, which in turn affects the meshing accuracy of the gears and causes timing errors. For example, the originally set 15 minutes may be shortened to 13 minutes or extended to a longer time. In addition, high temperatures will weaken the elasticity of the spring, resulting in insufficient rebound force after the timing ends, and the power supply may not be completely cut off, affecting the normal use of the equipment.

A key issue is the stability of the lubricant. Mechanical timers usually rely on high-temperature resistant grease to reduce gear friction, but continuous high temperature will accelerate the volatilization or carbonization of lubricants. Once the lubrication is insufficient, the resistance of the gears will increase during operation, which may cause abnormal noise or jamming. In more serious cases, direct friction between metal parts will cause the gears to wear more and even break, which will greatly shorten the service life of the timer.

The contacts of the timer are the core components that control the on and off of the current. Long-term high temperature will accelerate the oxidation process of the contacts. The oxide layer will increase the contact resistance, resulting in poor power supply, which may cause the connected electrical appliances to fail to start normally or work unstably. In addition, frequent switching in high temperature environments will also generate electric sparks, further ablate the contact surface, and shorten its service life.

The aging of insulating materials is also a common problem in high temperature environments. The plastic or rubber insulating parts inside the timer tend to harden and brittle at high temperatures, losing their original insulation protection function. This will not only affect the normal operation of the timer, but also increase the risk of short circuits and even cause safety hazards.

In order to extend the service life of the timer in a high temperature environment, the following measures can be taken: First, try to avoid using it in extreme temperatures and control the working environment temperature below 100°C, such as by strengthening heat dissipation or adjusting the installation position away from direct heat sources. Second, regular maintenance is essential. It is recommended to check the lubrication condition of the gears every 6 to 12 months, add high temperature resistant grease if necessary, and clean the contacts to prevent oxidation accumulation.

English

English 中文简体

中文简体