The Oven Mechanical Timer is a timing device designed based on the principle of mechanical transmission and spring drive. It is mainly used to control the working time of the oven and ensure that the baking process is carried out accurately according to the preset time.

Mechanical structure composition

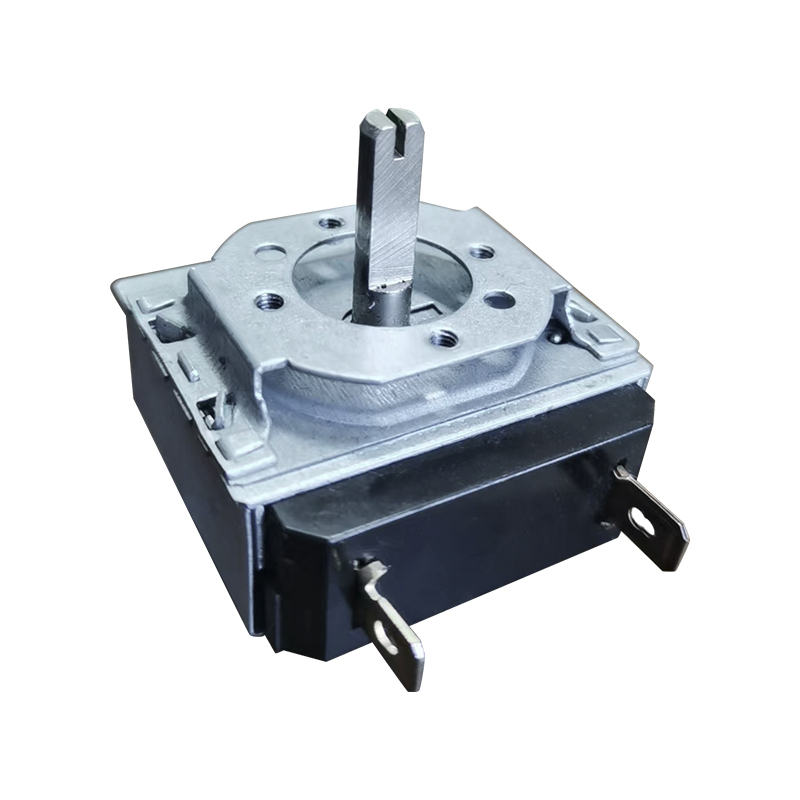

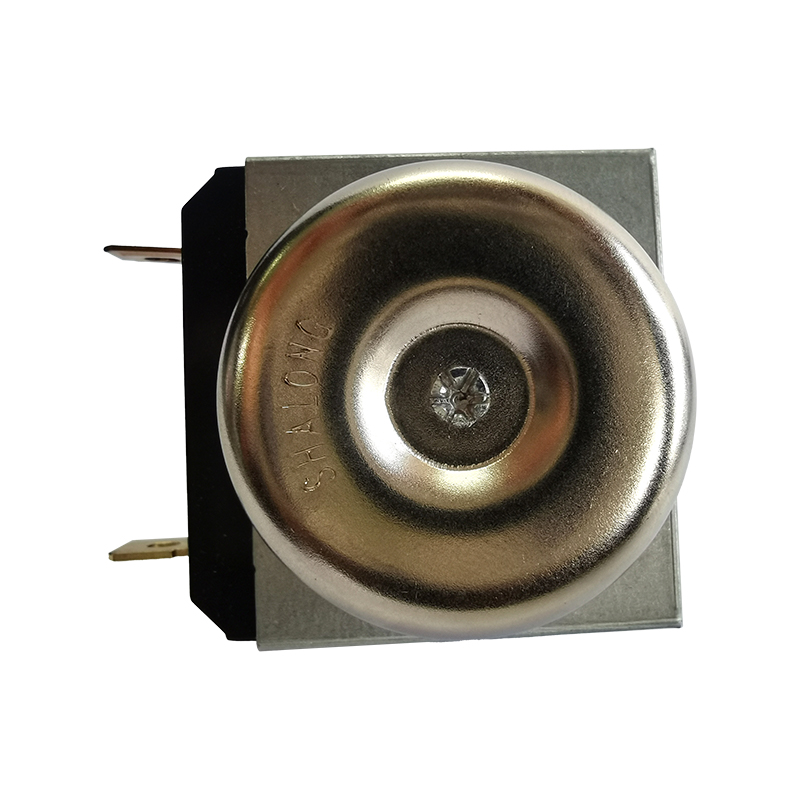

The Oven Mechanical Timer is mainly composed of rotating knobs, springs, gear sets, cams and contact switches. The user sets the required baking time by rotating the knob on the timer.

Energy storage and release

When the user rotates the knob, the internal spring is manually tightened to store mechanical energy. At this time, the spring is in a tense state and is ready to slowly release the stored energy.

Gear transmission control timing

When the spring is slowly released, it drives the gear set to rotate at a constant speed. The rotation speed of the gear is precisely designed so that the entire release process corresponds to the set time length, such as 30 minutes or 60 minutes.

Time counting and contact control

Driven by the gear set, the cam gradually rotates. When the time set by the knob is reached, the cam pushes the contact switch to act. The contact switch is disconnected or closed to control the circuit of the oven, thereby automatically cutting off the power supply and stopping heating.

Automatic reset mechanism

When the time is up and the spring is released, the mechanical timer will automatically reset to the initial position, and the knob will bounce back to zero, ready for the next use.

Safety and stability

Due to the mechanical structure, there is no need to rely on electronic components. The mechanical timer has strong anti-interference ability and high temperature resistance, which is suitable for use in high temperature environments such as ovens.

Application scenarios of Oven Mechanical Timers

Oven Mechanical Timers are widely used in various ovens and related equipment due to their simple structure, convenient operation and good high temperature resistance. Specific usage scenarios include:

Household electric ovens

The most common application scenario. Mechanical timers help users set baking time, realize automatic power off, avoid over-baking or burning of food, and improve cooking safety and convenience.

Commercial ovens

Such as ovens in commercial kitchens such as restaurants, bakeries, and cafes. Mechanical timers can meet the needs of long-term continuous use, support high-intensity operations, and ensure the quality and efficiency of baked products.

Industrial baking equipment

In baking and drying equipment on industrial production lines such as food processing plants and pharmaceutical plants, mechanical timers are used to control process time to ensure that products meet production standards.

Laboratory Oven

An oven used for heating and drying samples in the laboratory. The mechanical timer controls the heating time to ensure the accuracy and safety of the experimental process.

Multifunctional kitchen appliances

For example, in multifunctional equipment such as air fryers, electric ovens, and baking ovens, mechanical timers are used as time control components to improve the intelligence level of the equipment.

Repair and replacement market

As a replacement part for the mechanical timer of the oven, it is widely used in the repair or upgrade of old ovens to extend the service life of the equipment.

English

English 中文简体

中文简体