Oven mechanical timers are widely used in various baking equipment, mainly to achieve precise time control, automatic power-off, and standardized process control. Whether in household baking appliances or commercial baking equipment, as long as heating time control and safety management are involved, oven mechanical timers can play a stable and reliable role, effectively improving baking efficiency and equipment safety.

Core Components in Household Baking Equipment

In the field of household appliances, oven mechanical timers are common standard configurations: household electric ovens, air fryers, multifunction electric ovens, small household pizza ovens, tabletop baking cabinets.

Application value: realize timed heating, automatic power-off protection, prevent over-baking and burning, simplify operation processes.

Example data: the baking time for cakes in ordinary household electric ovens is about 25–40 minutes; mechanical timers can achieve minute-level precision control, with typical errors ≤±5%.

Stable Timing Control Systems in Commercial Baking Equipment

In commercial equipment, oven mechanical timers emphasize stability and durability: commercial deck ovens, hot-air circulation baking ovens, commercial pizza ovens, chain bakery shop ovens, food processing drying ovens.

Performance advantages: high-durability mechanical structures, stable operation under continuous high-frequency use, suitable for high-intensity working environments, reduced risk of electronic system failures.

Process Control Components in Professional Baking Equipment

In specialized equipment, oven mechanical timers are often used for standardized production: food processing baking lines, industrial bread production equipment, automated biscuit production lines, pre-prepared food processing equipment.

Functional roles: unify heating time standards, improve product consistency, reduce manual operation errors, improve production efficiency.

Time Control Modules in Composite Heating Equipment

Oven mechanical timers are not only suitable for traditional baking equipment, but can also be used in: electric heating drying equipment, constant-temperature heating cabinets, industrial heat treatment equipment, food warming equipment. Their simple structure and high reliability make them suitable for equipment systems with high requirements for timing stability.

Comparison Table of Compatibility with Different Equipment Types

| Equipment Type |

Compatible with Oven Mechanical Timer |

Reason for Compatibility |

| Household electric oven |

Yes |

Timing + automatic power-off |

| Air fryer |

Yes |

Overheating protection |

| Commercial pizza oven |

Yes |

Stable high-frequency use |

| Deck baking equipment |

Yes |

Standardized process control |

| Industrial drying oven |

Yes |

Stable timing control requirement |

| Electronic smart oven |

Applicable after system compatibility |

Used as a backup control system |

Core Advantages of Oven Mechanical Timers

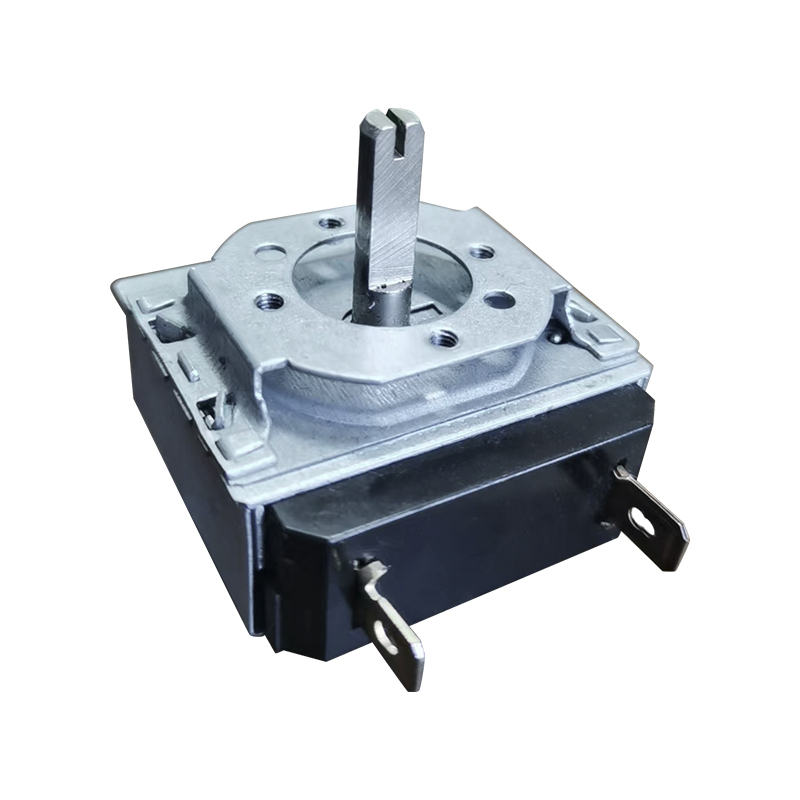

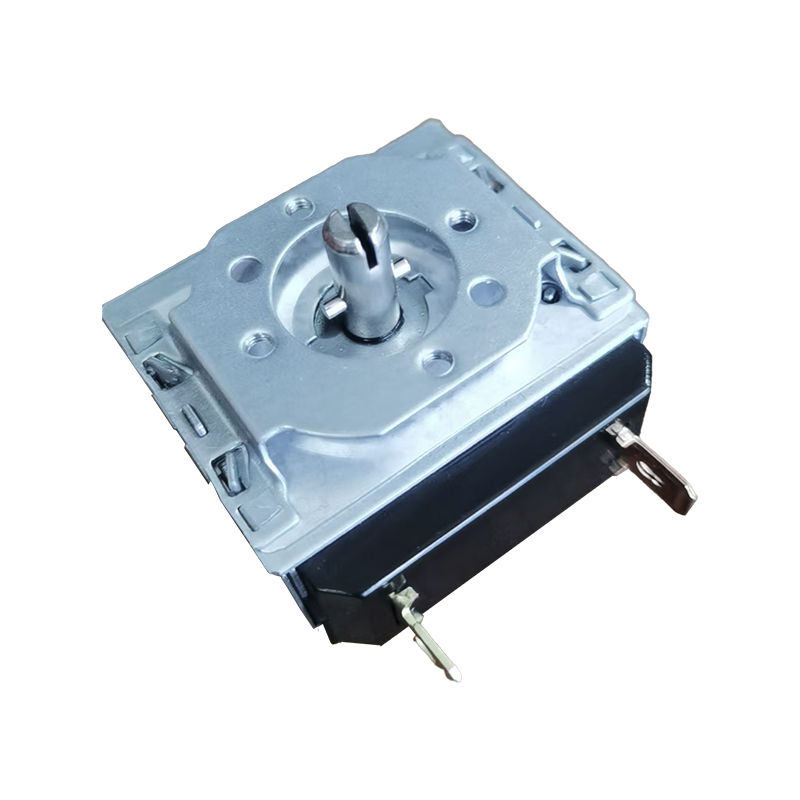

Core Advantages: They do not rely on electronic systems, have stable structures, strong resistance to high-temperature environments, long service life (commonly reaching 100,000–300,000 mechanical cycles), low failure rates, low maintenance costs, and intuitive operation, making them suitable for all types of users.

Selection and Matching Recommendations: Timing range (minute-level / hour-level), Rated voltage and current, Load power matching, Installation size and method, High-temperature environment adaptability, Whether automatic power-off function is included.

Example: Commercial pizza ovens usually have power ≥3 kW, requiring high-load oven mechanical timers, with rated current generally ≥16A, to ensure long-term stable operation.

Oven mechanical timers are not only suitable for traditional oven equipment, but are also widely used in household baking, commercial equipment, food processing, and industrial heating systems. Their strong stability, simple structure, and low maintenance cost make them indispensable timing control components in baking equipment. With the increasing standardization of equipment in the baking industry, oven mechanical timers are gradually upgrading from basic accessories to key control components, playing an increasingly important role in improving baking efficiency, safety, and product consistency.

English

English 中文简体

中文简体