In modern kitchen appliances, the oven mechanical timer is a core control component, and its accuracy directly determines the success or failure of baking. Many users wonder during the purchase or use process: why do timers from different brands differ in time control? What factors typically directly affect the timing error of an oven's mechanical timer?

Core Influencing Factors: Spring Material and Gear Transmission Precision

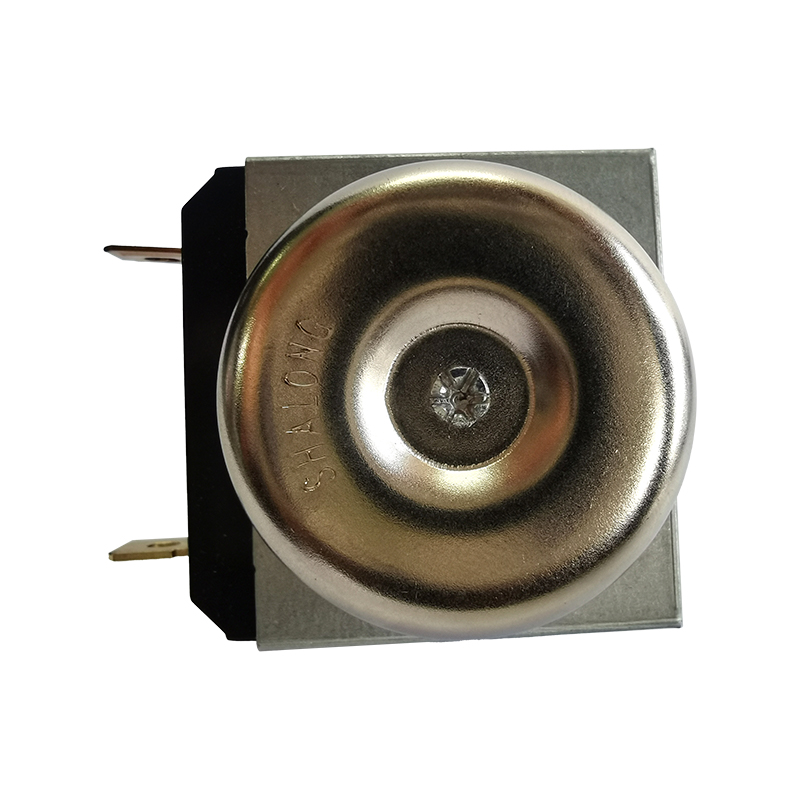

To understand the source of timing error, it's essential to understand the working principle of an oven mechanical timer. Essentially, it's a miniature "spring-loaded clock."

The Spring's Elasticity Coefficient (Torque Stability)

The mechanical timer's power comes from an internal metal spring. The primary factor affecting timing error is the uniformity of the spring material. High-quality timers use special spring steel, ensuring a constant torque is released at different torsion angles. If the spring material is poor, uneven force release at the beginning and end of the timing process will cause the time to be "fast at the beginning and slow at the end" or "slow at the beginning and fast at the end."

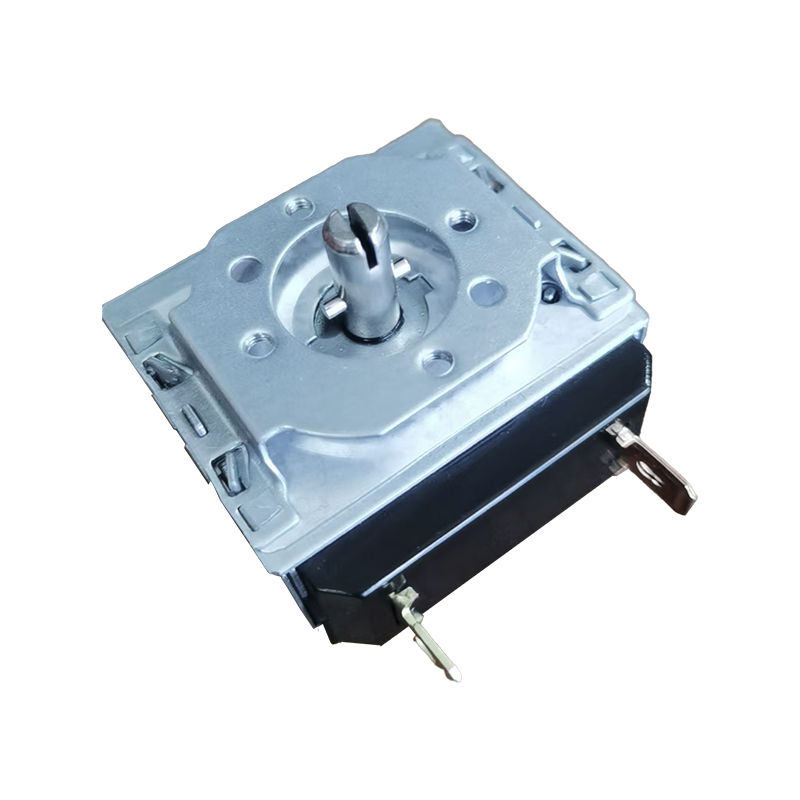

Gear Set Machining Accuracy and Meshing Degree

The energy released by the spring is transmitted through a series of tiny reduction gears. The precision of the gear module and the surface finish directly determine the frictional resistance during transmission. Burrs or center distance deviations in gear machining can cause instantaneous changes in resistance during operation, resulting in cumulative timing errors.

Other Environmental and Structural Variables That Cannot Be Ignored

Besides the core mechanical structure, oven mechanical timers are also affected by the following factors in practical applications:

- Ambient Temperature (T-level): The interior of an oven is a high-temperature environment. Although high-quality timers typically have a nominal temperature resistance of T125 (125℃), the slight thermal expansion and contraction of metal parts at extremely high temperatures can still cause minor adjustments in gear clearance, thus affecting the timing frequency.

- Lubricating Grease Volatility: To ensure smooth gear operation, a special damping oil is applied internally. If the lubricating oil is of poor quality, it is prone to drying out or becoming viscous at high temperatures, increasing mechanical resistance and causing the timing to slow down or even stop midway.

- Operating Habits and Preload: As we often mention in our product instructions, when setting a short time (e.g., 5 minutes), it is recommended to wind the spring for 15 minutes before unwinding. This is to provide sufficient initial torque to the spring. Insufficiently preloaded springs lack power at the start, which is the main cause of short-term time error.

How to Choose a High-Quality Oven Mechanical Timer?

As a professional oven mechanical timer manufacturer, we recommend focusing on the following indicators during procurement and evaluation:

- Certifications: Has it passed international safety and performance certifications such as UL, VDE, and CQC?

- Lifespan Testing: Standard products typically require over 10,000 rotational cycles without loss of accuracy.

- Contact Electrical Performance: For example, the commonly used 16A/250V specification ensures safe and stable control of the high-power heating element while timing.

The timing error of an oven mechanical timer is mainly affected by the stability of the spring power source and the transmission precision of the gear system. For manufacturers, precise mold design and strict material selection are the core barriers to controlling error.

English

English 中文简体

中文简体