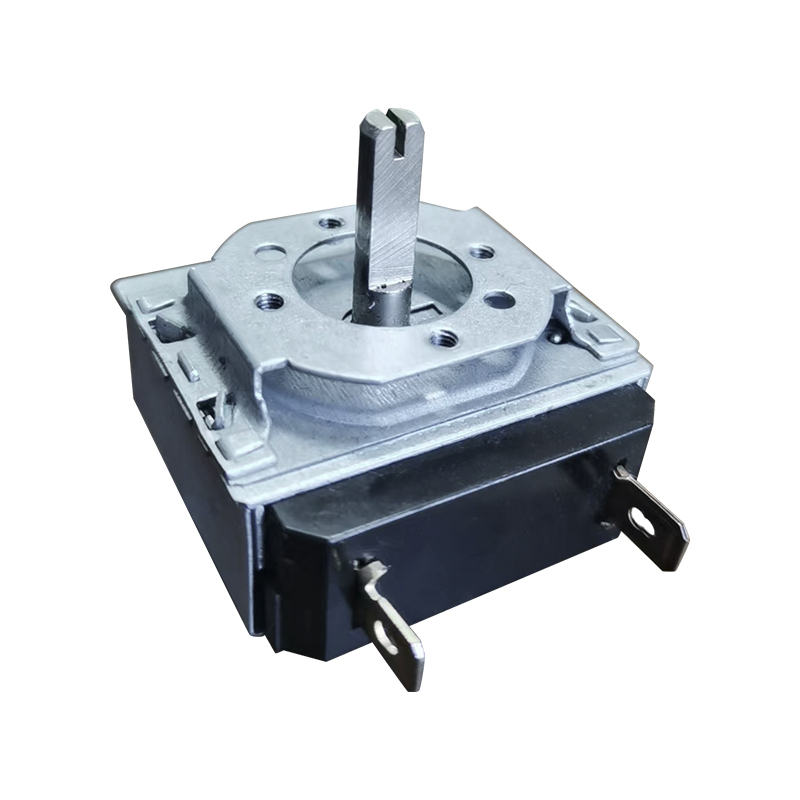

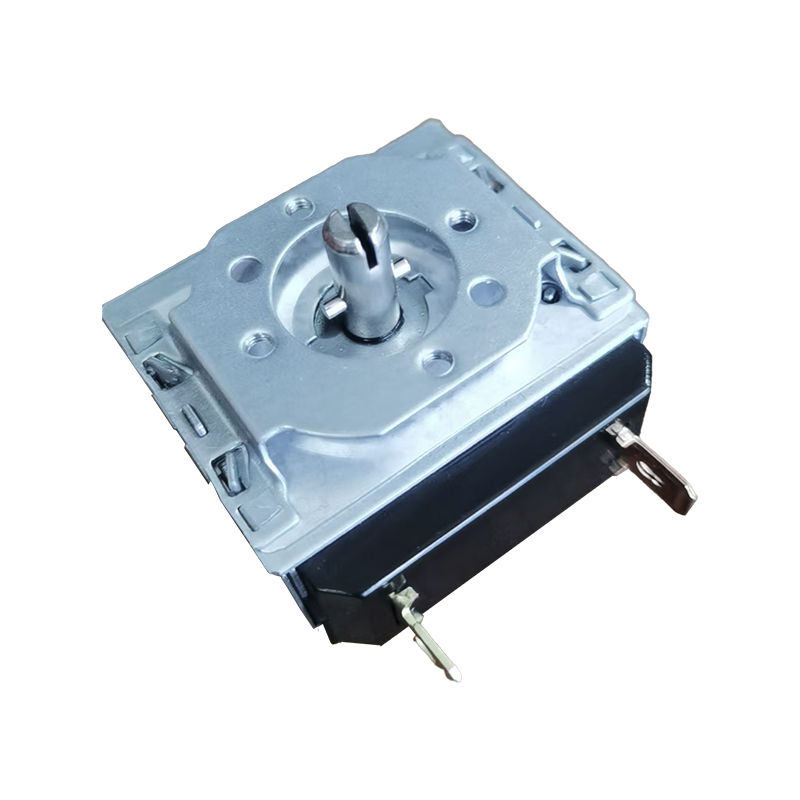

Mechanical timers play a crucial role in many kitchen and industrial appliances, especially in appliances like ovens that require precise time control. Despite advancements in electronic technology, mechanical timers retain their place due to their stability, durability, and lack of need for an external power source.

Core Structure Breakdown: The Four Key Components of a Mechanical Timer

The accurate operation of a typical mechanical timer (such as a common oven timer) relies on the following four interconnected key components:

1. Power and Energy Core: Mainspring

Function: The mainspring is the power source for the mechanical timer. When the user turns the timer knob, the mainspring is wound, storing mechanical energy.

2. The Precision "Heart": Escapement Mechanism

Function: This is the core of the mechanical timer's precise timing. It is responsible for evenly releasing the energy stored in the mainspring, ensuring the gears operate at a constant speed. Typically composed of an escapement wheel, fork, and balance wheel, it works together to control the frequency of the "tick" sound, ensuring smooth timekeeping.

3. The "Gears" of Time: Gear Train

Function: A set of precisely designed gears is responsible for transmitting the power of the mainspring to the output shaft and escapement mechanism, while simultaneously amplifying or reducing time (e.g., converting the second-level movement of the escapement mechanism into minute or hour timing).

4. Function Implementer: Cam and Contact System

Function: This is the actuator that executes the "power off" command of the mechanical timer. When the time reaches the set endpoint, the gear train drives the cam to rotate to a specific position.

Cam: A carefully designed shape used to push or release the switch.

Contact/Switch: When the cam is in position, it triggers the contact to open (power off) or close (power on), thereby stopping the oven's heating or other operations.

Criteria for Choosing a High-Quality Mechanical Timer

Although oven mechanical timers may seem simple, their internal structure is intricate. Defects in the materials and manufacturing processes of any critical component can affect the accuracy and lifespan of its time control. Therefore, when choosing a mechanical timer for your oven or kitchen appliances, it is recommended to focus on the following points:

- Materials and workmanship: The wear resistance of the mainspring and gears.

- Timing accuracy: The speed regulation stability of the escapement mechanism.

- Switch life: The high voltage and arc resistance of the contact system.

By understanding the internal structure of a mechanical timer, you can make a more informed choice, ensuring consistent baking results from your oven.

English

English 中文简体

中文简体