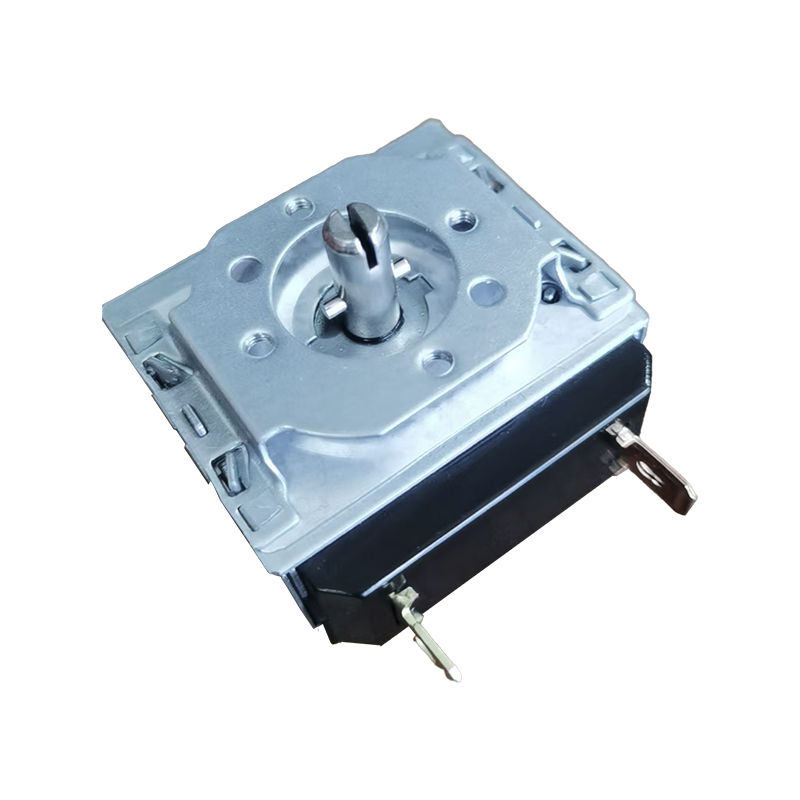

In the selection of components for commercial and household ovens, mechanical timers still dominate the kitchen appliance accessories market due to their extremely high temperature resistance, long lifespan resulting from their simple structure, and the core advantage of requiring no standby power consumption. Compared to electronic timers, which are susceptible to high-temperature electromagnetic interference and circuit aging, mechanical timers, driven by a physical spring mechanism, provide precise power-off protection in extreme baking environments, making them the preferred choice for manufacturers seeking cost-effectiveness and high reliability.

Why are mechanical timers irreplaceable in high-temperature environments?

With the development of intelligent kitchen appliances, while electronic displays are aesthetically pleasing, the industrial characteristics of mechanical timers demonstrate a significant competitive advantage in high-heat environments like ovens. Here's a detailed analysis of their core advantages:

1. Excellent High-Temperature Resistance and Anti-Interference Capability

The internal working environment of an oven is complex, with extremely high instantaneous temperatures. Electronic components (such as capacitors and LCD screens) are prone to screen blackouts, program malfunctions, or solder joint failures under continuous high temperatures. Mechanical timers, however, are made of all-metal or high-strength temperature-resistant materials, contain no complex integrated circuits, and are completely immune to electromagnetic interference, ensuring stable operation even in enclosed high-temperature cavities.

2. Simple Structure, Longer Lifespan

The lifespan of electronic timers is often limited by the half-life of electronic components, and once damaged, they are usually irreparable and require complete replacement. Mechanical timers are based on the classic spring mechanism and gear transmission principle, resulting in a robust physical structure. As a professional timer manufacturer, our products undergo rigorous cycle life testing before leaving the factory, ensuring crisp feedback and accurate timing even after tens of thousands of uses.

3. Zero Power Consumption and Environmental Friendliness

In today's world of energy conservation and emission reduction, the advantages of mechanical timers are becoming increasingly apparent. They rely entirely on physical mechanical energy for operation and consume no electricity in standby mode. For export ovens requiring international energy efficiency certification, using a mechanical structure can significantly reduce the overall standby power consumption.

4. Intuitive Operation and Extremely Low Maintenance Costs

The "twist and use" operation logic is very user-friendly for users of all ages. For after-sales maintenance, mechanical timers have simple wiring and strong universality. When a timer malfunctions in an oven, repair personnel can quickly diagnose and replace it, significantly reducing the brand's after-sales labor costs and spare parts inventory pressure.

How to choose a high-quality mechanical timer supplier?

When choosing a mechanical timer, it's important to consider not only the timing range (such as 15 minutes, 60 minutes, or 120 minutes), but also the material and current-carrying capacity of its contacts. A high-quality timer should have the following characteristics:

Contact capacity: Able to withstand high current loads such as 15A/250V.

Material standards: Compliant with international safety certifications such as UL, TUV, and CQC.

Audible alert: A clear mechanical bell sounds at the end of the timing period to remind the user that cooking is complete.

Although digitalization is the trend, in the field of baking equipment, where extreme stability, cost control, and durability are emphasized, mechanical timers remain an indispensable "heart" component. For oven manufacturers, choosing a stable and reliable mechanical timer lays a solid foundation for product safety and reputation.

English

English 中文简体

中文简体