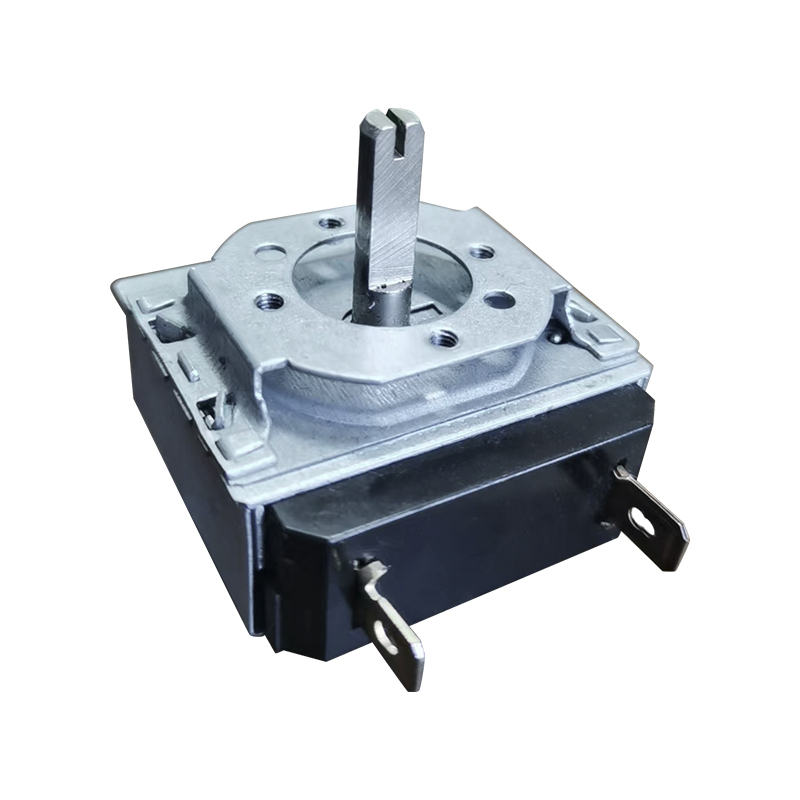

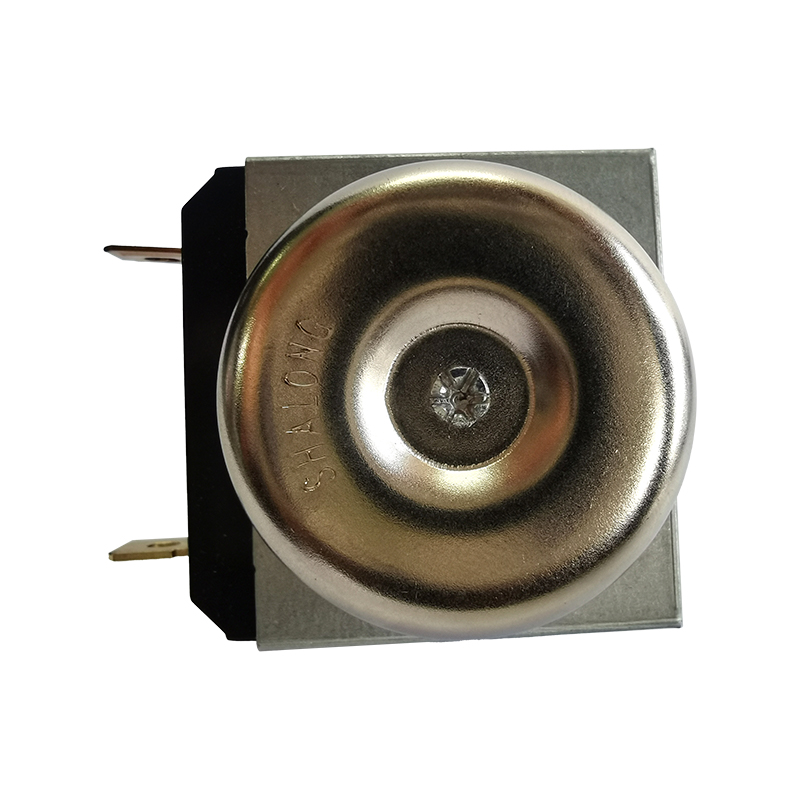

Since the operating temperature range of the Baiting Machine High-Temperature-Resistant Metal Mechanical Timer is -10°C ~ +125°C, long-term exposure to high temperature environment may affect its mechanical structure, contact life and lubrication performance. The following are detailed maintenance suggestions to ensure its long-term stable operation.

In high temperature environment, grease, food residue or dust can easily adhere to the inside of the Baiting Machine High-Temperature-Resistant Metal Mechanical Timer, which may hinder the operation of the mechanism or cause contact oxidation. To keep the timer working properly, it is recommended to regularly use a soft cloth or a small brush to remove surface dirt. Avoid using strong acid and strong alkaline detergents when cleaning to avoid corrosion of metal parts. Especially when used in an oven or microwave oven, make sure that there is no accumulation of food splashes around the timer to avoid high temperature carbonization, which makes it more difficult to clean.

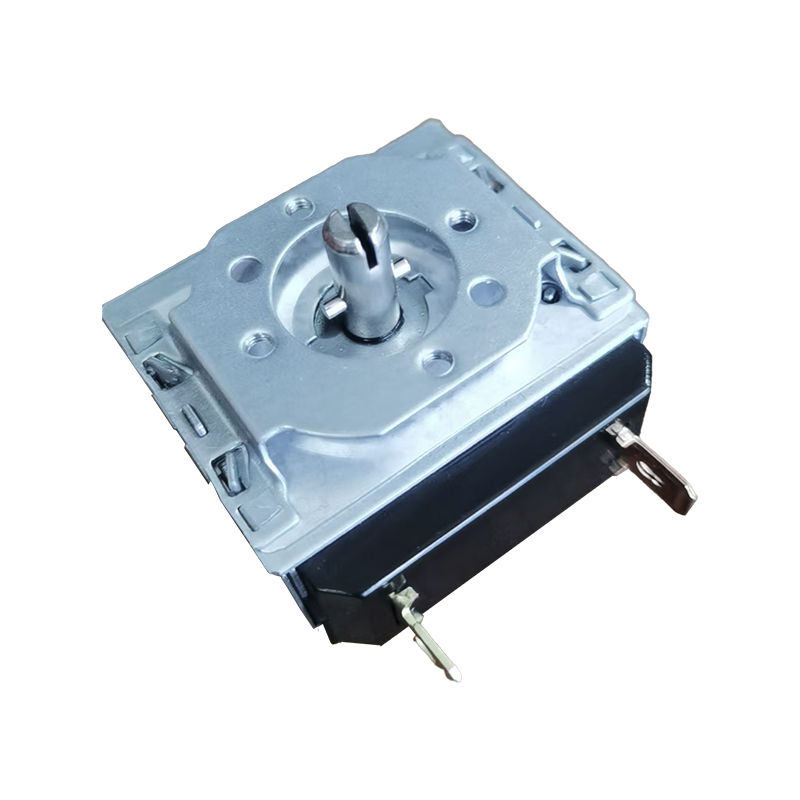

High temperature may cause the original lubricating grease to dry or volatilize, resulting in increased friction of the gears, affecting the timing accuracy, and even causing the machine to jam. To maintain smooth operation, high temperature resistant lubricants should be selected, which can withstand ambient temperatures above 125°C. It is recommended to check the gears and shafts every 3 to 6 months and add lubricant if necessary. However, care should be taken to avoid excessive lubrication to avoid dust absorption, which will affect mechanical operation.

Although the timer is resistant to high temperatures up to 125°C, long-term exposure to extreme temperatures may accelerate metal fatigue or embrittlement of plastic parts. To ensure its service life, it should be installed in a well-ventilated location and avoid being close to heat sources. If the internal temperature of the device may exceed 125°C, it is recommended to install an insulation layer or choose a timer with a higher temperature resistance model to reduce the damage to the internal structure caused by high temperature.

High temperature environment may accelerate oxidation of contacts, especially in the case of frequent switching of large currents, which can easily lead to a decrease in conductivity. It is recommended to check the contact condition once a year. If oxidation is found, gently wipe it with fine sandpaper or contact cleaner. If the contacts are severely ablated, the timer needs to be replaced to ensure safe and reliable circuit switching.

Sudden cooling from a high temperature environment may cause deformation of metal parts or failure of seals. Therefore, during maintenance, the device should be allowed to cool naturally to room temperature before cleaning or inspection. At the same time, avoid spraying detergent or water directly under high temperature to prevent damage to the internal structure due to rapid cooling.

English

English 中文简体

中文简体