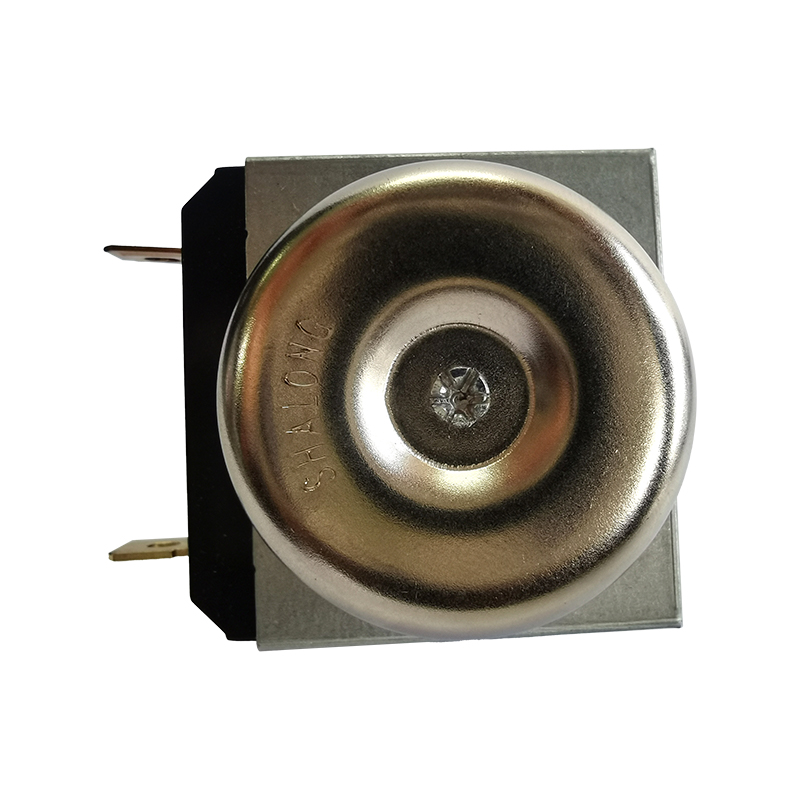

The working principle of a Circular Mechanical Timer For Oven is based on a simple mechanical structure, which uses a spring and gear system to control and time the time. Its core components include a spring mechanism, a gear system, and a contact switch, which work together to achieve the timing function.

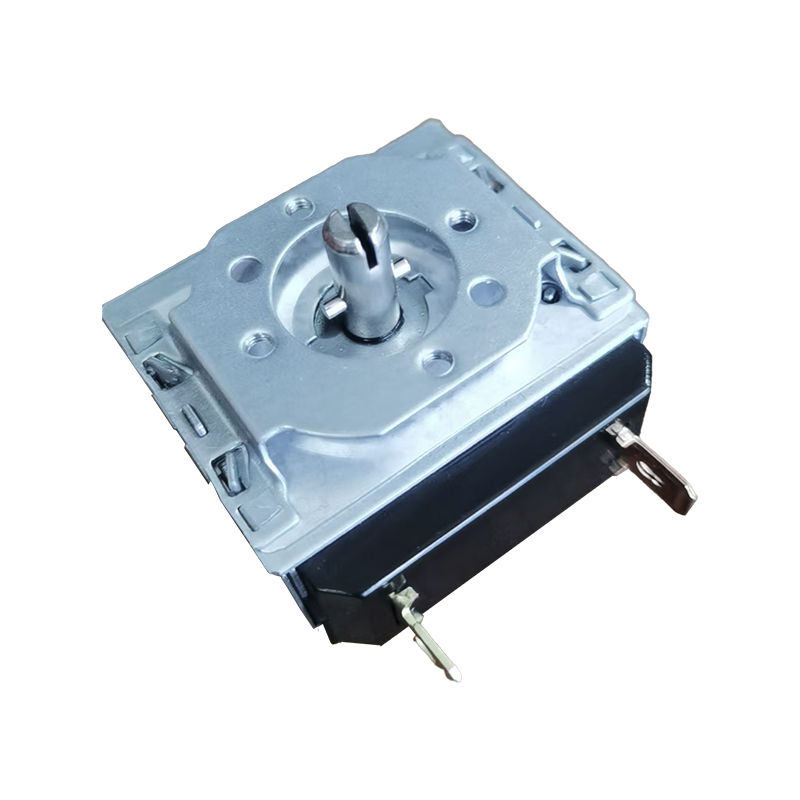

The user sets the required time through a knob or button. The knob is usually marked with numbers or scales and rotates clockwise or counterclockwise to adjust the required time. Pay attention to the direction when setting to avoid damaging the movement. Once the time is set, the spring mechanism begins to load, and the gear system slowly unfolds or advances at a consistent speed, depending on the tension of the spring and the structure of the gear.

When the set time is reached, the gear system triggers the contact switch to cut off the power supply to the heating element, thereby stopping heating. At the same time, the timer will emit a buzzer or light prompt to remind the user that the time is up. This mechanical timer does not require electrical drive and has the advantages of stability, reliability, energy saving and environmental protection.

Mechanical timers usually have a long service life, and some models of mechanical timers are designed to have a service life of more than 50,000 operations. Users should avoid frequent force or repeated adjustments to avoid damaging the movement.

Round mechanical oven timers usually use a spring mechanism and a gear system to achieve time control. The user sets the desired time through a knob or button. The knob is usually marked with numbers or scales and rotates clockwise or counterclockwise to adjust the desired time.

Once the time is set, the spring mechanism begins to load, and the gear system slowly unfolds or advances at a consistent speed, depending on the tension of the spring and the structure of the gear. When the set time is reached, the gear system triggers a contact switch to cut off the power to the heating element, thereby stopping heating.

Stable and reliable: Mechanical timers do not require batteries or electronic parts, are not affected by power fluctuations, and are stable and reliable.

No power supply required: Most mechanical timers do not require an external power supply, but rely on mechanical devices to drive, so they can work normally even if there is a power outage.

Energy saving and environmental protection: No additional electricity or batteries are used, saving energy.

Simple operation: Users can set the time through a knob or button, and the operation is simple and intuitive.

Long life: Some models of mechanical timers are designed to have a service life of more than 50,000 operations.

High accuracy: Manufacturers calibrate mechanical timers for precision during the manufacturing process to ensure the accuracy of timing.

Strong applicability: Mechanical timers are widely used in kitchens, laboratories and other occasions that require timed operations.

Round mechanical timers usually have a simple and practical design, with scales from 0 to 60 minutes or longer on the surface, which is convenient for users to set the time accurately. There is usually a knob in the center of the timer for adjusting the time, and there may be a lever on the right side for locking or unlocking. When installing, you need to consult the manual, turn off the power, connect the wiring, identify the wires and connect them correctly, fix the timer, reassemble the control panel, and test the function.

Mechanical timers differ from digital timers in operation and display methods. Mechanical timers use mechanical mechanisms to set and measure cooking duration, and the time is displayed on a dial or digital scale, while digital timers rely on electronic components and displays.

English

English 中文简体

中文简体